nicolavivanet.net

Main menu:

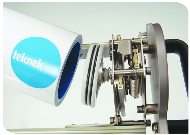

Teknek

PCB solutions

Why Teknek?

Teknek are world leaders in manufacturing solutions for the contact cleaning sector. With operating facilities throughout the world and an intricate understanding of the client's manufacturing process, Teknek have been the first choice supplier to their customer base for nearly three decades. An ethos of continuous innovation and improvement means that the company remains at the forefront of yield improvement solutions for the many sectors in which it operates.

Technology

Teknek Cleaning Technology is based on a roller system and follows the following steps....

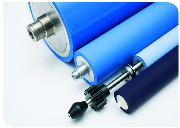

* An elastomer roller runs in contact with the substrate to be cleaned.

* An adhesive roll then runs in contact with the elastomer roller.

* The contamination is transferred from the elastomer roller to the adhesive roll, where it is trapped and not re-attracted to the elastomer roller. This is possible due to the surface tension on the adhesive roll being greater than the surface energy of the elastomer roller.

. Click to see how does it work

Many solutions for each cleaning need

ROLLERS

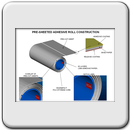

The adhesive roll is reverse wound. Therefore, when the surface of the adhesive is fully loaded with contamination, the Pre sheeted adhesive roll is simply unwound one revolution which drops away, thus providing a fresh adhesive surface in contact with the elastomer roller.

Teknek have invested heavily in the Research and Development over the last 20 years to ensure the best possible cleaning performance from the Teknek elastomer rollers and adhesive rolls.

ADHESIV ROLLERS

The function of the adhesive roll is to pick up and hold the maximum number of particles without allowing these particles, or the adhesive, to transfer back onto the substrate. Using internationally recognised testing procedures, (e.g.FINAT) Teknek measure the various characteristics of the adhesive roll to calculate the optimum "Cleaning Performance Index".

Perchč l'adesivo pretagliato č meglio?

Error 76: Path not found

NOVITA': sistema pulizia FastPad

Error 53: File not found

The FastPad is the first fully automatic cleaning station designed to compliment the Teknek DCR range of hand held contact cleaning rollers. (Image: fast pad staticUsing the Fast pad to clean the glass frame of an automatic exposure unit.)

The FastPad uses the proven Teknek Cleaning Core (TCC), Teknek polymer rollers and Teknek pre-sheeted adhesive rolls, creating the world's most efficient cleaning station.

When the hand roller is placed into the FastPad holder, a small low voltage motor is activated and the adhesive roll revolves, cleaning the DCR.

The unit has a small foot print taking up a small part of the working area, if preferred it can be wall mounted.

Support and partnership

At Teknek we understand that customers who choose our clean machines are making an investment. Choosing the world's highest performing clean machines is an investment in overall manufacturing efficiency and end customer quality.

Once installed, our clean machines become a critical component of production lines - increasing yields, reducing scrap and driving overall production costs and end of line quality in the right direction.

For this reason, Teknek offer a full range of customisable after sales support to help our customers continually achieve the optimum performance from their clean machines.

Elastomer rollers